Additionally, components such as gongs and dials were usually handled by specialty suppliers and were seldom made by the movement manufacturer. The same basic design layouts were made by several movement manufacturers during the 1925-1960 period with little difference besides the finer details and perhaps build quality. Most proprietary movements for the German and British trades tend to look very similar because these movements were farmed out to casemakers who required similar movements to work with. So this is actually a fairly striking find in my experience. I've been at this game for a while now and I know how hard it usually is to find donor parts which will move from one movement to another.

About three layers down I came across the old Enfield and the module of the chime barrel teeth look promising at a glance so I pulled it out for a closer look. I only twigged to it myself because the URGOS came in with some serious damage from spring breakage so I went for a half-hearted look in my graveyard of donor movements not expecting to find anything. But this is different because I'd never heard of a connection. The Schatz / GUFA / JUBA models are one of the most obvious but there are a few others. I know it's not that rare to see similar clocks being produced by related firms where family connections or buyouts are pretty much common knowledge. I thought I'd simply put it up on the forum to see whether anyone actually KNEW anything about it. All of the possibilities you mentioned had already occurred to me. I've never heard anyone mention a connection between them so I was intrigued to find these two movements which shared so much 'DNA' in common. I am aware of the basic histories of the two companies.

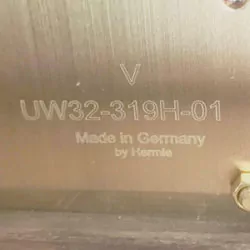

The plates have exactly the same measurements and distance between the front and rear plates likewise. Apart from those things just about everything is interchangeable. The winding arbors use a different design to make barrel removal possible but winding arbors from the barrels on one clock match the barrels from the other clock. The set up for the chime assembly has been redesigned and the lever for the strike hammers that runs across the outside of the rear plate also. Also the crutch and pallet arbor bridge are different. The Enfield uses a simplified version of depthing adjustment for the fly pinions. The rack and rack hook and gathering pallet have been reworked but the basic geometry is the same. The position of the warn wheel on the chime train might have shifted by about 1 millimetre. I think there is one position where that may not be true. As I said upthread, you could take any wheel assembly out of either clock and drop it into the corresponding position on the other clock and both wheel and pinion would mesh with the corresponding gears above and below in the train. Closely compare the pattern of the hole layout.

0 kommentar(er)

0 kommentar(er)